Discover Precision Engineering

In the realm of aviation, there is no room for compromise. Our aviation parts embody this principle, crafted from the finest materials to ensure they withstand the rigors of their application. Each component, from aerodynamic profiles to intricate engine parts, is produced with aerospace-grade precision. Utilizing advanced manufacturing techniques, we ensure that every part adheres to the strictest aerospace standards, delivering unmatched performance and reliability.

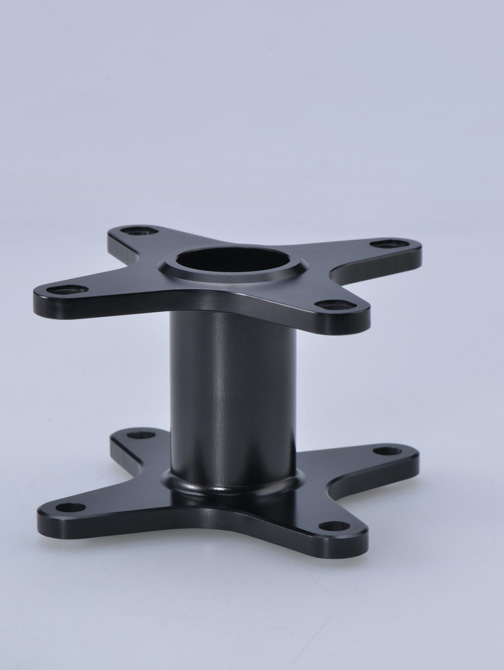

Our tooling solutions are designed to revolutionize your manufacturing process. With products ranging from high-precision jigs and fixtures to complex molds, we provide the tools necessary for enhancing productivity and achieving impeccable accuracy. These solutions are engineered to facilitate efficient, repeatable production processes, enabling our clients to maintain the highest levels of quality control.